First of all I want to get across that I find nothing wrong in the Squirrel design and it most likely will fly perfectly well built stock per the instructions. I have been trying to go for a record duration flight with my Squirrel planes and have been putting in almost 1000 turns into the rubber motor by using a winder. There are a couple of things I have noticed after repeated flights like this.

The physics of the rubber motor is that most of the torque is released in the first few seconds and then it tapers off quickly. If you have ever seen the lift equation for flight, you know that the velocity component is squared. What this means is with the initial burst of speed as you launch your Squirrel model there is excess lift and it will most likely climb very steep. So much so that it is almost vertical and hanging on the propeller, the plane can do some crazy gyrations at this point but recovers and continues flying.

To improve on this I have been experimenting with more “downthrust” which means moving the angle of the propeller shaft at an angle downwards. This technique has been used in model planes for a long time of all types of propulsion, not just rubber power. The beauty of this is that the force pulling the nose downward is greater when the thrust is greatest which is exactly what is needed. The plastic propeller nose pieces that are included with planes like the Squirrel have some downthrust built-in but I think more might be required. There was enough play in the motor stick that I just glued the plastic to the balsa with the prop shaft headed down. It would be better to shim this down from above and experiment with varying degrees of downthrust.

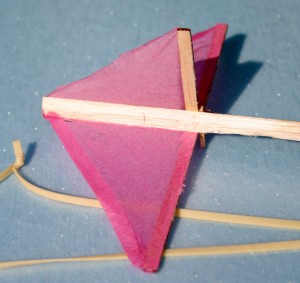

After many flights on some of my Squirrel planes I have noticed the tissue had a tendency to tear on the winglets leading edge. Not sure if this was from repeatedly crashing into an obstacle or if the edge of the tissue starts to flutter. The fix I have been experimenting with is to leave an extra border of tissue on the winglet , putting glue in this area, and then folding it over to create an edge of double covering. I also did this on the trailing edge of the stabilizer too.

I hope this article gives people a couple of ideas to experiment with; I really need to experiment further with this and give better explanations. It would be nice to know just how many degrees of downthrust is optimum. That I do not know and it could vary between planes. My technique for folding the edges could be refined also.

Great ideas.

Lately I’ve been cutting the winglets and tailplanes with a curve bulging outward. Then the cut is not along the line of tensile force in the tissue. Seems to help a bit.

I will have to try that also, was hoping that my ideas would inspire to try other adjustments.

Bill