I have a new way of holding the wheels on the axles. I use a leather punch or paper punch to make 1/8″ disks from HDPE can lids. These are the same disks I use to make pin clamps. I push a pin through the center of the disk. The disk is forced over the end of the wire axle, which has been filed round. It grips tightly enough to stay on, yet the wheel can be removed and replaced without bending or cutting the wire.

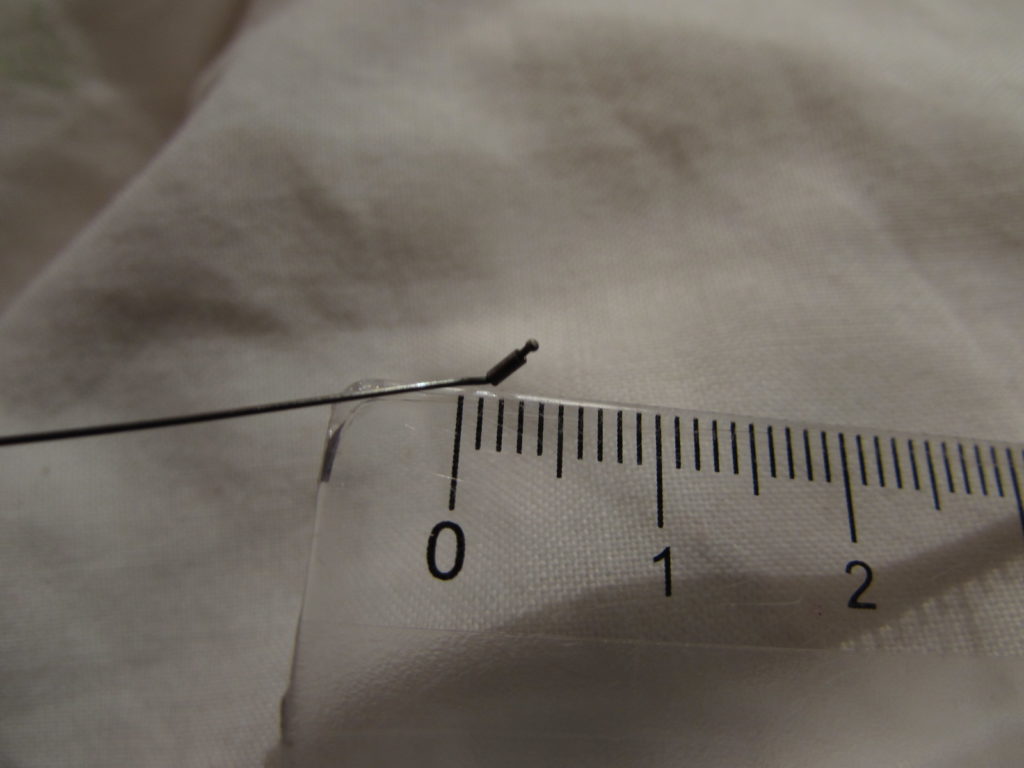

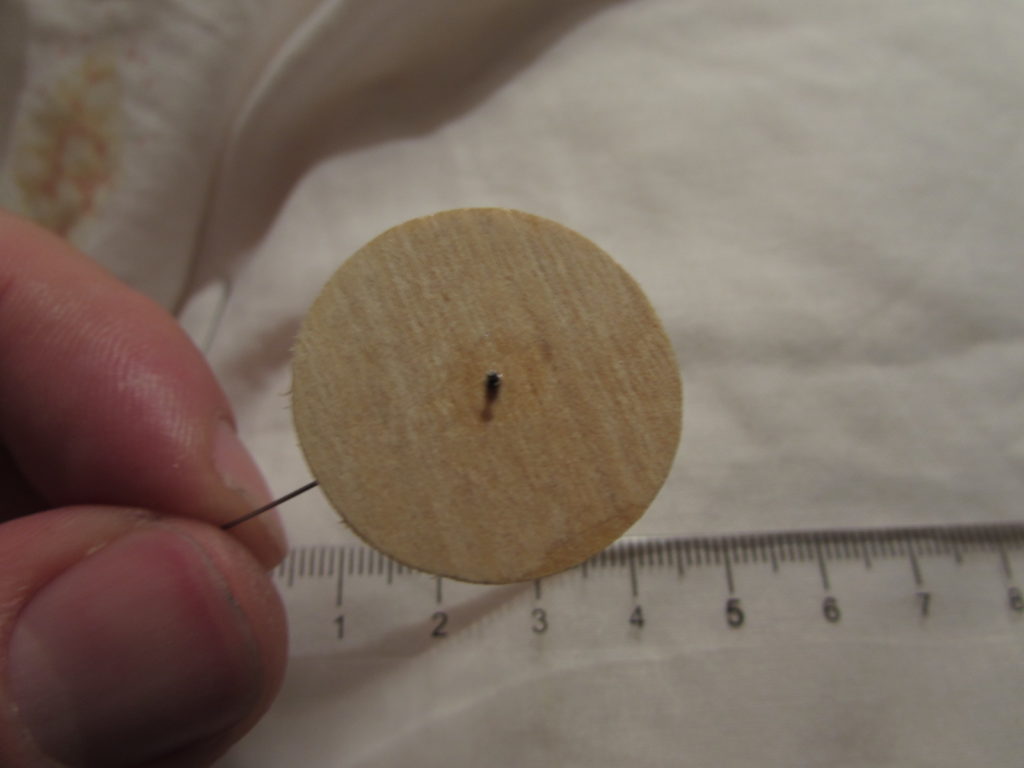

Federico Conci described his method of retaining wheels in the comment below. He sent me these two pictures.

Quite nice! First time I comment on this page, however I usually come here to learn. Great page by the way. I do this: I put a syringe needle piece as a bushing first. Needles come in a variety of sizes and diameters. Then I WELD, YEAH, SPOT welding with an ATX power supply +12V connected to a copper rod electrode. A ball is formed in the wire end avoiding the bushing to escape. The diameter of the weld ball is IN BETWEEN the needle inner and outer diameter. By this way I later drill the balsa wheel to fit the needle outside diameter and I glue with little cyano and big care for alignment balsa-bushing. This is much lighter, smaller, aesthetic and sturdy than any other way. I encourage to experiment on that and make a post on it. If you send me an email I have a picture of the result.