Dihedral means two surfaces. In the simplest form, this means the left wing and the right wing are each in a different plane; they are set at an angle to each other so that each makes a small angle to the horizontal, with the tips higher than the center. Sometimes there are more than two wing panels, a configuration we call polyhedral.

The purpose of dihedral is to provide stability in roll. Roll is a rotation around the longitudinal axis, a line that runs through the nose and tail of the airplane. Stability is the tendency to return to a desired trim condition following a disturbance. With a glider, disturbances occur in the form of air turbulence. With powered models, the torque of the motor is a continuing disturbance that must be constantly balanced.

There are things you can do to demonstrate the importance of dihedral and how it works.

The AMA Alpha, assembled according to the instructions, has no central dihedral. The molded wings have tip dihedral, but we will find that this is not enough to keep the wings level. Try flying the AMA Alpha with the wings in this configuration. Carefully observe the flight. Pay attention to angle of bank, sideslip, turn, climb and flight circle diameter.

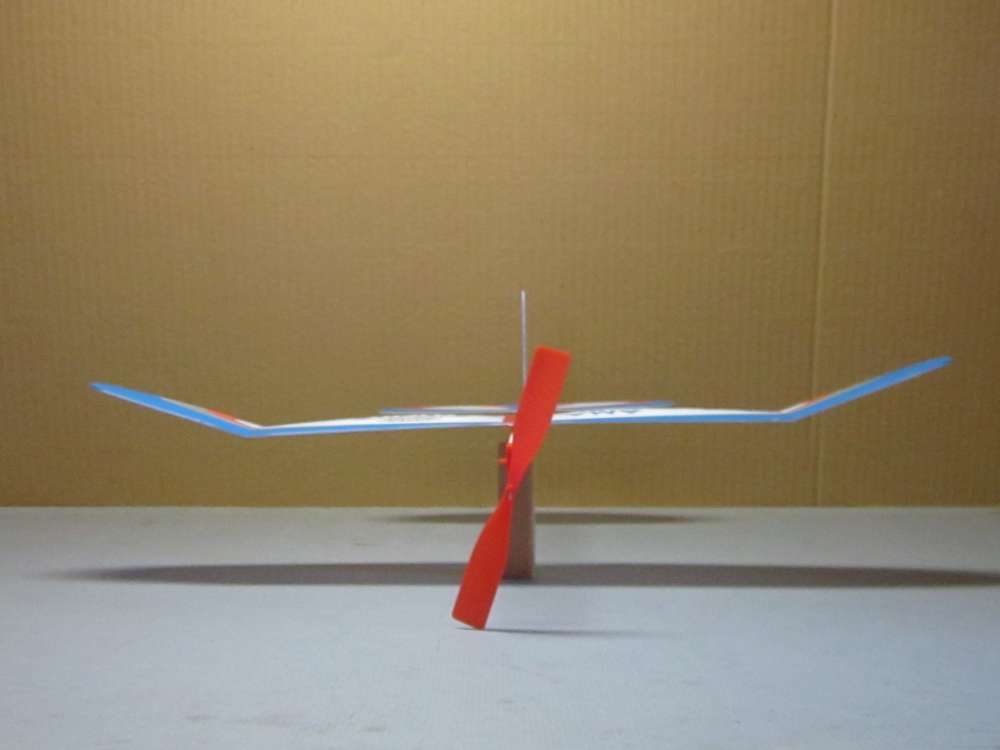

I got the airplane flying well with dihedral in the wings. I replaced the wing with a set without dihedral. I put 1,500 turns into the 16″ loop of 3/32″ rubber strip and the video shows what happened. The plane has a right handed prop. When the motor is wound to turn the prop the correct direction, it puts a left rolling torque on the rear hook, turning the left wing down. With the left wing down, the wing lift tilts to the left, the plane sideslips to the left, the sideslip hits the fin on the left side, causing the plane to turn down and the plane dives right into the ground. We might be able to fix this by adding right thrust to the propeller, adding right turn to the rudder or deflecting the left aileron down and the right aileron up to produce a right roll. But all of these fixes cost energy and energy is time.

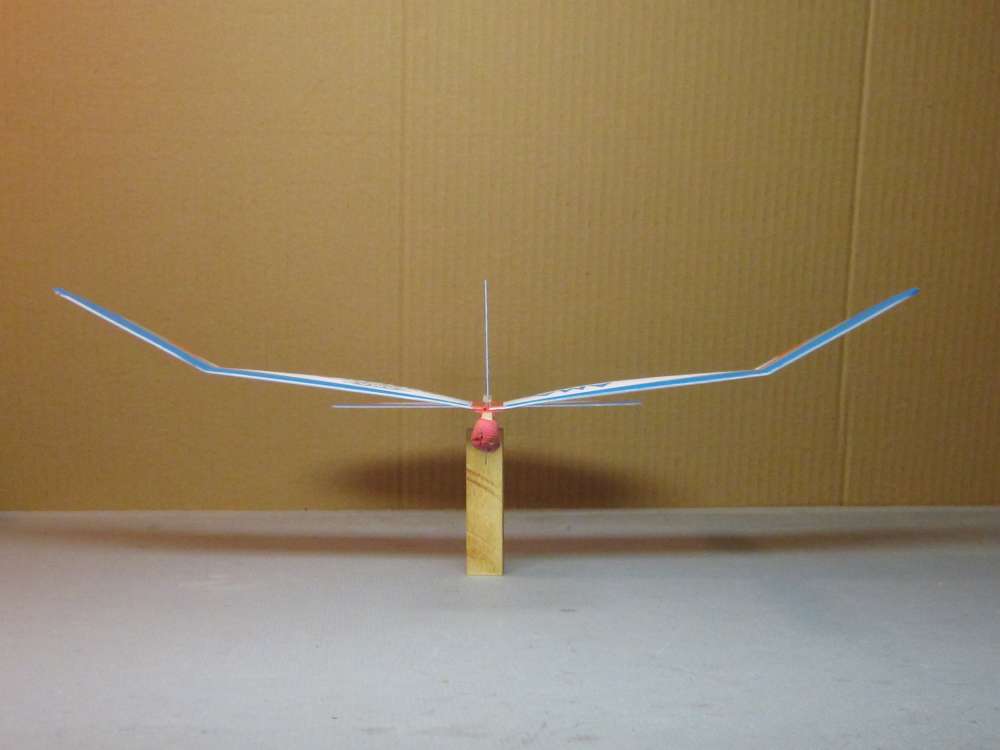

Here I have added central dihedral as originally designed by bending the metal tabs that were added to strengthen the wing roots. You can read about that in my post on the AMA Alpha. Then I flew the plane with the wing in the same position as previously, also with 1,500 turns in the 16″ loop of 3/32″ rubber strip. The video shows what happened. Do this yourself and carefully observe the flight. Pay attention to angle of bank, sideslip, turn, climb and flight circle diameter. You can see that the plane maintains a constant angle of bank and rate of turn. It makes a nice long flight, circling to its left.

You can demonstrate how dihedral works very simply. Put some turns into the motor, enough so that when you hold the plane by the prop in still air, the plane rolls left. Now hold the plane up and run backwards, creating an airflow past the plane. (You might be able to do this with a natural wind, if it is very steady in speed and direction.) Then rotate the plane to point a little to its right. With the right combinations of speed and angle, the rotation will stop. You can do this with other planes, such as the AMA Cub.

This tells us something about how dihedral works in flight. The motor torque banks the plane left, the plane side slips left and the sideslip, acting on the wings at different angles, increases the lift on the left wing while decreasing the lift on the right wing, producing a right rolling moment. The sideslip acting on the fin also produces a left turn. With proper design, the plane will find an angle of bank and turn rate that makes a proper turning flight of long duration.

Gary, you article dihedral was excellent. Copied it and placed it in my file. Question regarding the rubber motor winding, how do you prevent the motor from bunching and subsequently sliping off. you after say 600 turns or more. Also, what type of stooge do you use for stick fuselage planes?

Joe

I use a hook that prevents the motor from slipping off. You bend the usual loop in the wire, but leave enough on the end to cross over the open end. Leave a short piece crossing over so the inside end of the loop blocks the motor from slipping off the end. The loop is a right handed helix to match the usual right handed twist in the rubber, making it try to twist on instead of twist off. Also, I use an O-ring on the winder end of the motor and the opening in the loop is a slight friction fit for the O-ring. You don’t want enough friction to make it difficult to get a tightly wound, lubricated motor on the hook, just enough so the unwound, slack motor won’t slip off the hook. I show an example of this right handed pigtail loop with overlapping end here, scroll down to TAIL HOOK: https://www.endlesslift.com/the-mystery-phantom/https://www.endlesslift.com/the-mystery-phantom/

I use a foot stooge to wind when I am alone on the field. I show one kind of foot stooge here: https://www.endlesslift.com/make-a-simple-foot-stooge/

Another kind is shown here, scroll down to FLYING THE PHANTOM: https://www.endlesslift.com/the-mystery-phantom/