Making the Wing Ribs

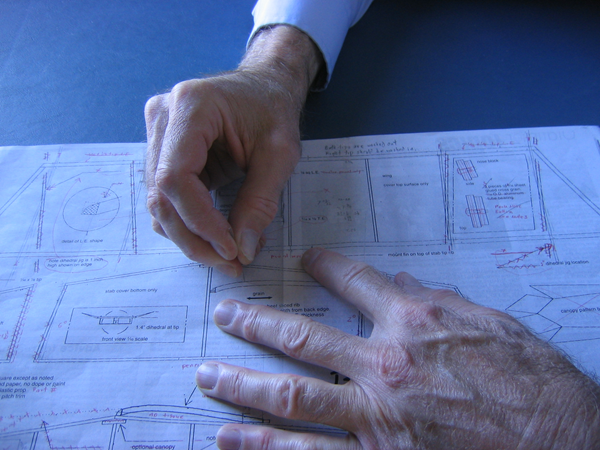

You will need a template or pattern for cutting out the ribs. This is made by putting a piece of cereal box cardboard under the plan and poking a pin through the drawing of the rib to make holes in the cardboard.

The rib pattern shown inside the tailplane frame is too long. Measure the length of the angled ribs, the ones at the dihedral break line. If you changed the angle of these ribs, measure along the new rib length. Draw a vertical line that same distance back from the front end of the rib drawing. The three center ribs that go straight across the wing are slightly shorter. These ribs will be trimmed to length just before they are glued in. Poke holes every 1/8″ along the top curve and the two points on the ends of the bottom curve, 1/8″ below the ends of the top curve.

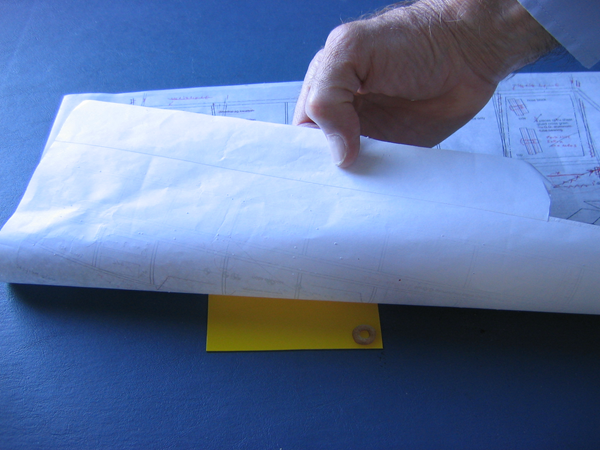

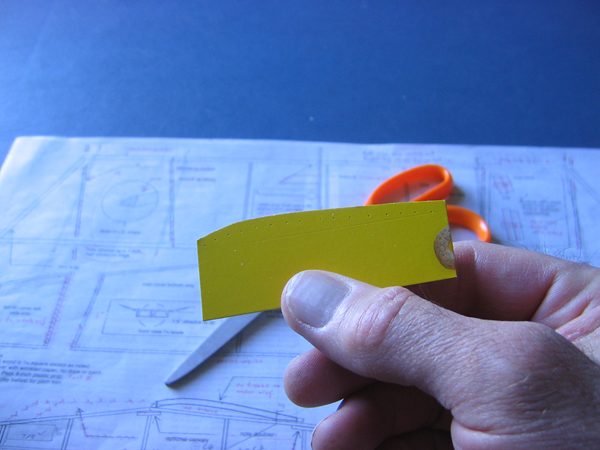

Cut along the curve with scissors. With a straightedge, cut a 3/4″ wide rectangle below the curve. (You can use this alone as a pattern to cut out the ribs, moving it up 1/8″ to cut each successive rib, but the following produces a template that automatically sets the rib height and makes measuring each rib height unnecessary.)

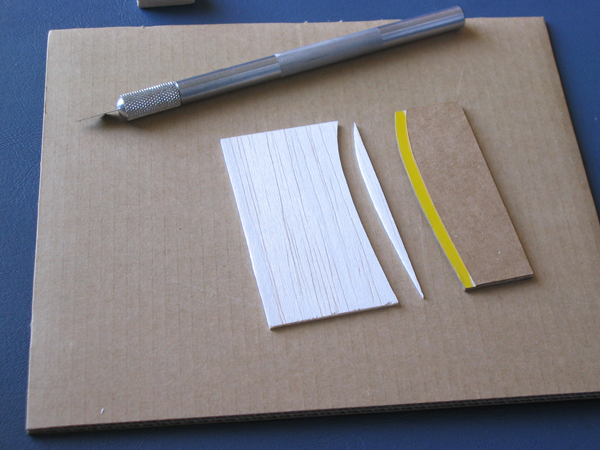

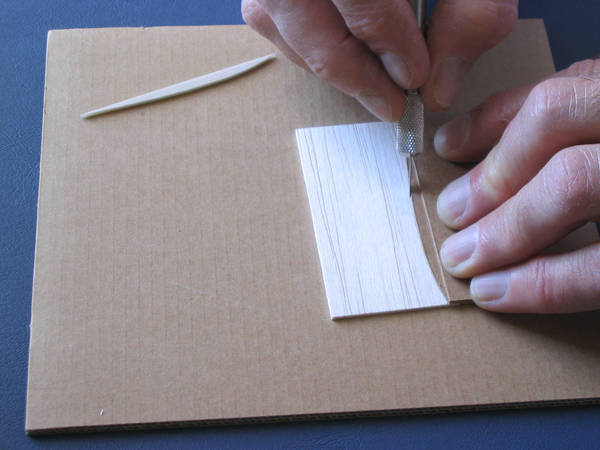

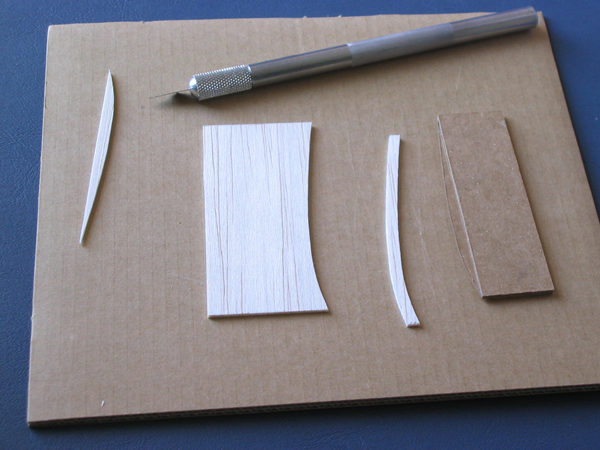

Use this pattern to make another with a 7/8″ rectangle below it. Also cut out a rectangle 7/8″ wide. Glue these three together with the straight bottom edges together and the taller piece in the center. The next few pictures show the finished template in use. To make ribs, start by placing the straight edge against the edge of the 1/16″ x 1″ x 2 3/4″ balsa piece and cut along the curve with a sharp blade. Make several gentle slices with the knife using light pressure. Cutting through gradually will produce neater work. This forms the undercamber of the first rib. The cutoff piece is waste.

Remove the thin cutoff, turn both the wood and the template over and place the lower curved cardboard against the undercamber curve on the balsa and cut the upper camber with the knife.

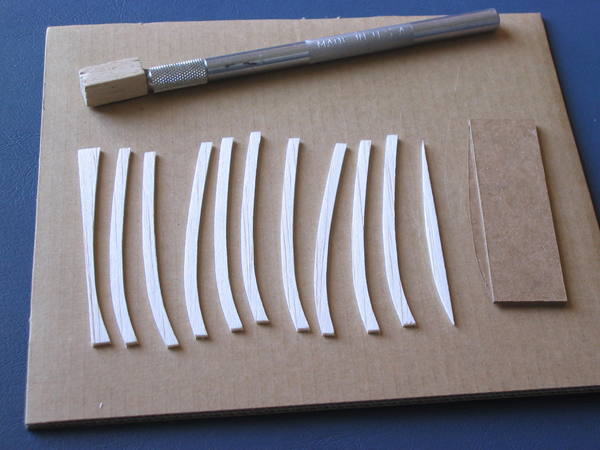

This produces a 1/8″ high curved rib.

Continue in this way until you have made five ribs. Put these ribs in a safe place.

I started with a wider piece than necessary and made more ribs than necessary, enough for two airplanes. Note that when the cutting is done, the knife goes back in the balsa block sheath to avoid poking fingers.

Making the Noseblock

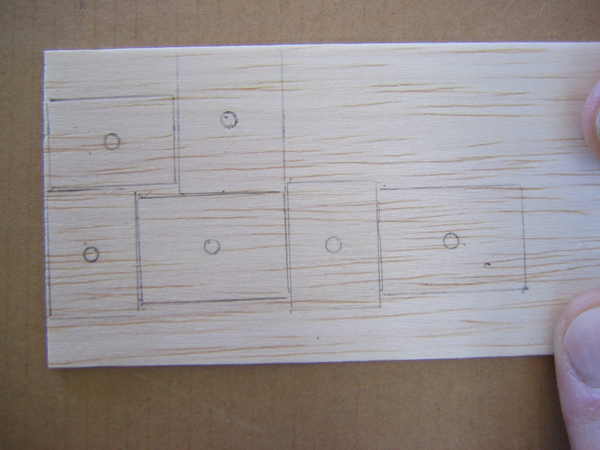

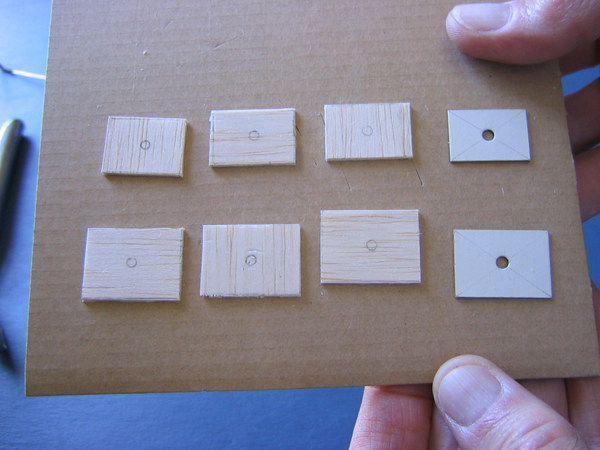

The noseblock is laminated from six pieces of 1/16″ thick sheet balsa. The noseblock parts are cross grain. That means the grain direction in each piece is perpendicular to the grain direction in the adjacent pieces. The front piece has horizontal grain, the next is vertical, then horizontal, vertical, horizontal and finally vertical again. (Note: I found that a lighter nose block was required to get proper balance with a lighter motor. It is made from three layers instead of six, a single front plate with horizontal grain, a plug piece with vertical grain and another plug piece with horizontal grain.) Use the hardest part of your sheet for the first and fourth pieces, you may use lighter wood for the rest. It is difficult to make the pieces of the noseblock so they align perfectly around the Nylon prop bearing and fit smoothly into the opening at the front of the fuselage. Start by making very precise cardboard patterns with a 1/8″ hole in the exact center. The front pattern is as wide and deep as the front end of the fuselage, you can measure the dimensions off the plan. Mine is 1″ x 23/32″. The smaller nose plug pieces are 1/16″ smaller in each direction, 7/8″ x 19/32″. I use a leather punch to make the holes, but a round jeweler’s file works well, too. Draw diagonal lines between the corners to locate the center of each rectangle. Measure 1/16″ out from the point of intersection in all four directions. You can use a circle template, very carefully centered, to draw the holes before punching or filing. You can see the finished patterns in the following pictures. Put the pattern on the 1/16″ sheet and pencil around the perimeter and inside the hole, keeping the pencil perpendicular to the wood. The pencil line is a bit wide of the edge.

Then cut the pieces out a wee bit outside the pencil mark.

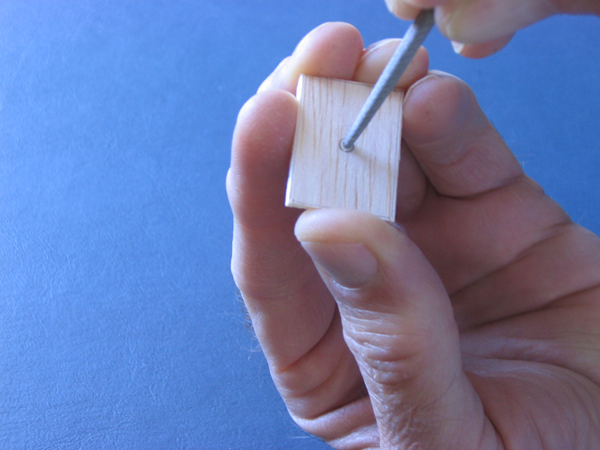

Drill the holes very carefully with the round file, keeping the file exactly centered in the pencilled circle.

Check frequently in both side and top directions that the file is perpendicular to the plate.

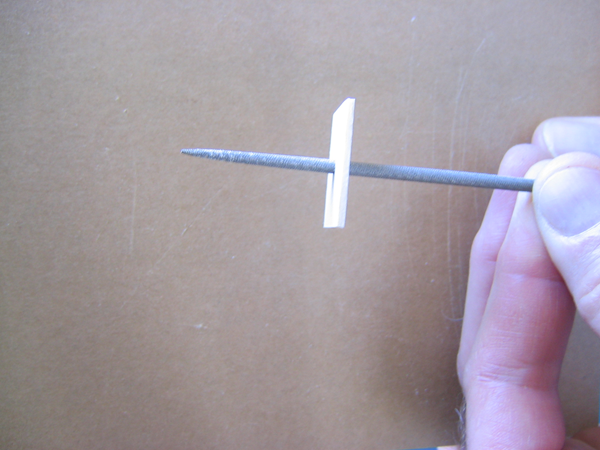

Align the pattern and the part on a short bit of waxed 1/8″ dowel and trim around the edges with a razor blade.

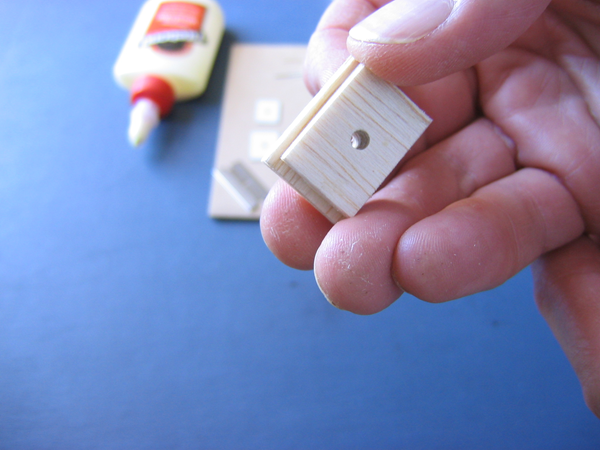

The result is a set of parts that closely match the patterns, and some shavings.

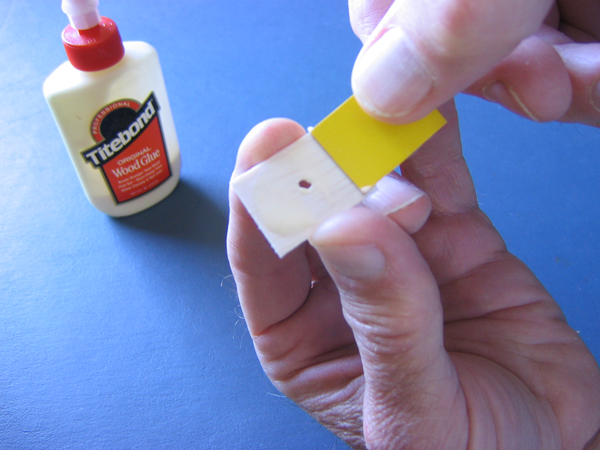

The six parts of the nose block are laminated cross grain. The first piece should be made of the hardest wood from the sheet to keep the prop bearing from working loose. (Note: later I added a 3/8″ diameter washer of 1/32″ plywood to the front of the noseblock.) The grain should be horizontal. Spread glue on this piece with a small rectangle of cardboard.

Thread it and the next piece onto the waxed piece of 1/8″ dowel and press them together. Use candle wax or crayon wax, rub it in with a rag or paper towel. The wax keeps the glue from sticking to the dowel. Align them carefully so the edges match and the dowel is perpendicular to the face when viewed from two perpendicular directions. Spread glue and add each piece in succession, twisting the dowel after each piece has been pressed in place to keep it from sticking. After the glue has started to gel, check that everything is properly aligned, the peg should be square to the faces from top and sides,

then gently twist the dowel and withdraw it from the hole. Let the glue dry. Here is the finished nose block.

You do not want it to look like this!:

This Pussycat block was aligned with a 1/16″ x 1/8″ stick, not a dowel! The peg is not perpendicular with the faces and the plane would not fly properly.

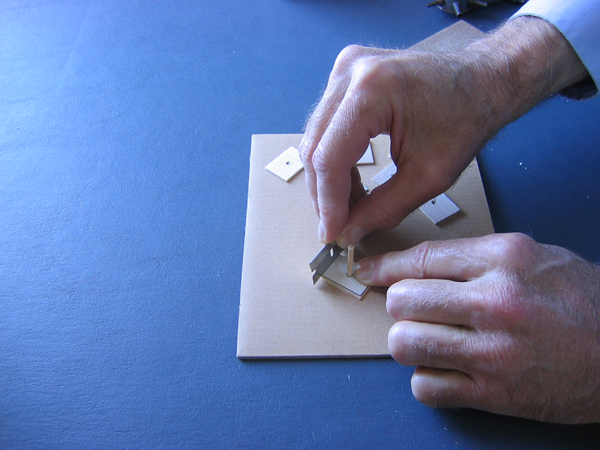

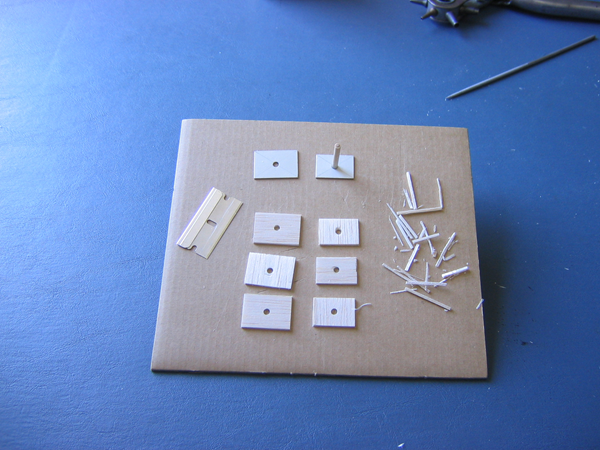

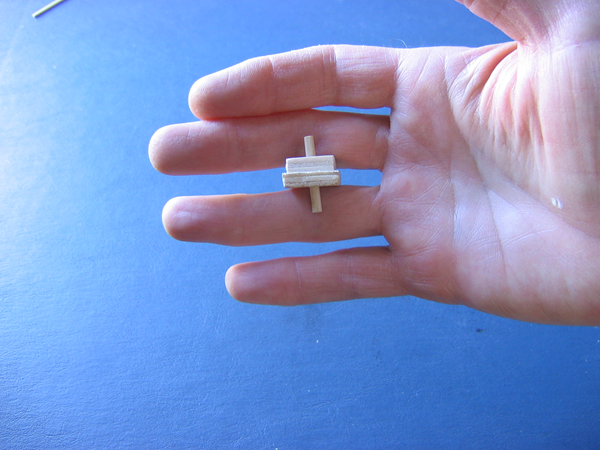

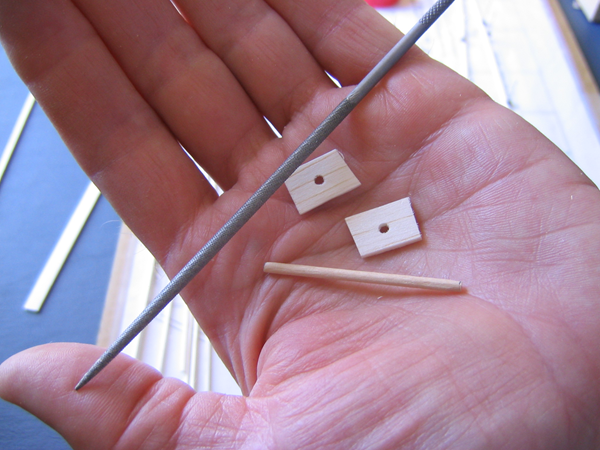

Making the Motor Peg Anchor Plates

With enclosed fuselage models, it is common to have the motor loop around a wood or aluminum peg that passes through holes in the sides of the fuselage. The holes are bored in sheet balsa anchor plates. These are best made after the longerons are pinned to the plan, but we can make them now and you can final trim to fit later, if necessary. If you are careful, they won’t need any further trimming. These are made from the 6″ of 3/8″ wood we cut out with the Master Airscrew stripper. Sand one end of the 3/8″ strip square. If you have the longerons pinned down, place the square end against the lower longeron, over the anchor plate drawing and mark the top edge with the razor blade, otherwise place it directly over the drawing. Cut it a bit long and angle sand it to the razor line on the sanding jig. Use the first one to mark out another on the 3/8″ strip, leaving it a bit long on both ends and sand to the razor lines on the sanding jig. I use a small circular file to bore the holes. To get them lined up hold the two pieces together next to the drawing and push a pin through both where the drawing shows the hole. The pin hole will mark where to drill with the file.

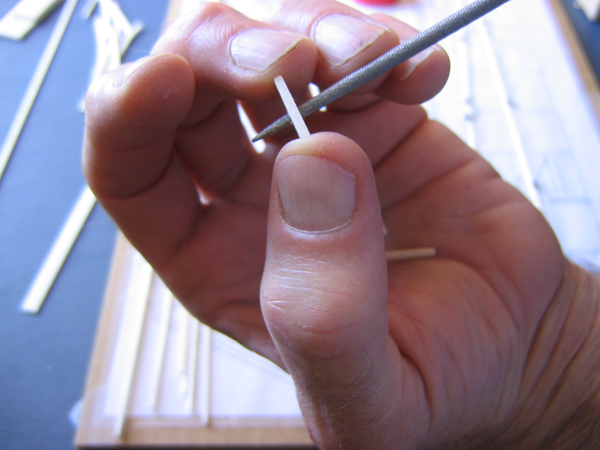

When drilling with the file, test the fit of the motor peg very frequently, every two or three strokes of the file as you get close to final size. You want the motor peg to be a snug friction fit in the hole. It should slide easily through, but require a little pushing. Make the hole perpendicular to the plate.

Put them in a safe place until you are ready to use them. I keep all my little pieces in a Ziploc baggie or a candy box.

Click HERE to go to Chapter 4.

you tip for making wing ribs helped me so much. before cutting a set of wing ribs for a very small indoor plane i found this page (chapter 3) so with each rub cut i just slid the template up until the offset lower layer fit against the balsa and cut the next rib. so easy–and these under-cambered ribs are 0.75mm x 0.75mm x 59mm.

i am looking forward to seeing the other chapters!