Alternate Cloud Tramp Prop Shaft Bearing Ideas that Pete Money has COLLECTED

Adjustable Prop Bearing by Bob Morris

The photo shows my current CT adjustable front end design. It is made from 3/4″ 6061-T6 aluminum angle (available at http://www.metalsdepot.com) and two 2-56 screws. Earlier versions were made from aluminum brackets found in the small hardware drawers at Sears Hardware but they had a tendency to get bent by crashes. The Al part has a 1/8″ hole which accepts a Peck Polymers nylon bushing. The prop shaft and bushing are lifted out of the Al part through a slot in the top for winding from the front. The set screw at the rear adjusts down thrust and bears against a small piece of stainless shim stock glued to the top of the stick. The hold-down screw goes into a threaded hole in a small piece of Al sheet embedded between the bottom of the stick and the thread binding. There is a small piece of sandpaper glued under the front of the Al part to prevent side-to-side slippage. The Al part and two screws weigh in at 1.6 grams. This is working very well and gives stable fine adjustment of thrust.

I find that more and more down thrust and less side thrust are needed as winds increase. I think that the stick is bending some under the tensile load from the rubber. I have considered adding some carbon fiber reinforcement along the bottom of the stick but this could be considered to be not in the spirit of the design. In lieu of this I will look for stiff light sticks and tune for high power climb.

Bob Kopski’s CT Front End Modifications

Some additional details about the 2 such assemblies I’ve tried on CTs include the use of three 2-56 nylon adjusting screws bearing against the 1/64″ ply capped balsa nose pieces shown.

The nose front piece itself is a lamination of 2 cross grained 1/16″ balsa pieces capped both sides in 1/64″ ply. The 3 nylon screws are tapped into this assembly.

The 1/16″ prop shaft has as a bearing a short piece of 1/16″ ID brass tubing epoxied in place along with some wood bushing extensions on both sides of the nose plate. This assembly is keyed on two thru-dowels and held to the CT nose balsa with a rubber band. So far all seems well operationally.

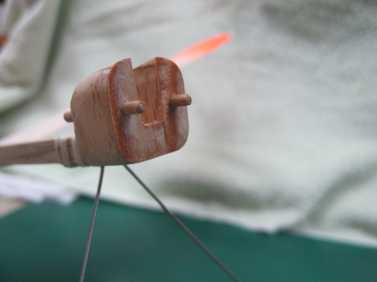

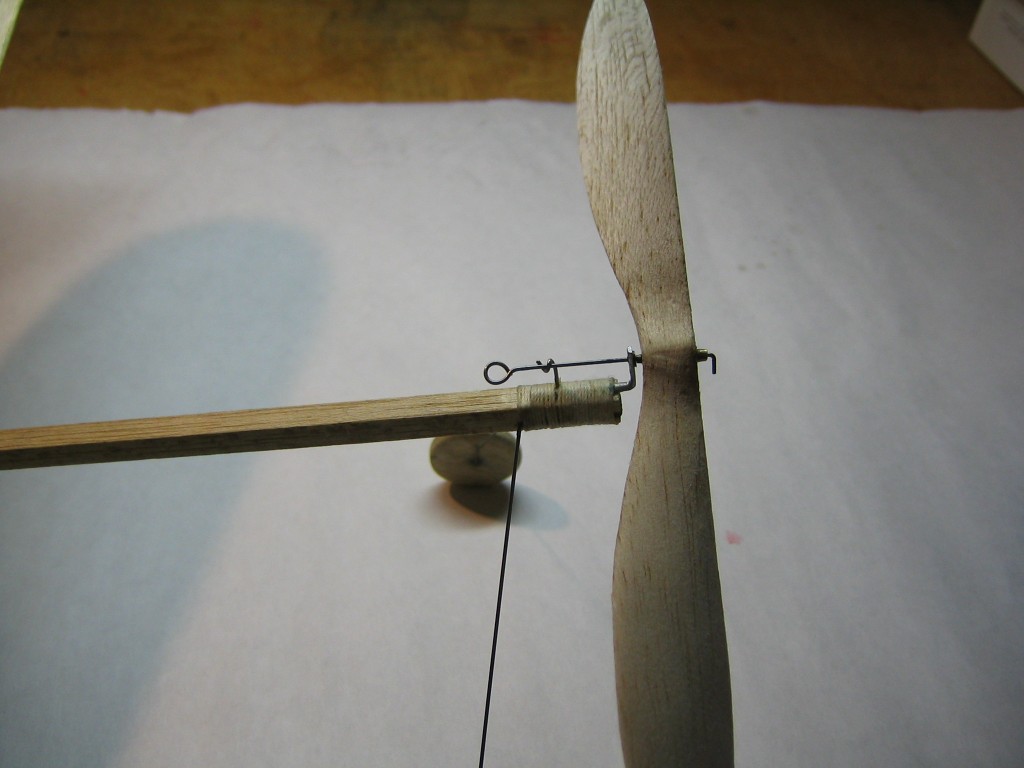

two point support bearings by gary hinze

When flying with long motors such that the prop will freewheel for some distance in the descent, the single hole bearing lets the prop flail around, causing the Cloud Tramp to wander from its circular flight. This can cause a lost Cloud Tramp when flying from a small field. I made this rear bearing from wire, with a pigtail so the prop shaft could be removed from the bearing. The front is the original bearing. The hook can be threaded through the pigtail. I found that this would loosen the wire. I would recommend making the entire thing from a single piece of wire, with a zig-zag base on top of the motor stick to stabilize it.

I also made a two hole bearing from a cotter pin, as seen here. This does not permit removal of the prop without cutting the shaft. It does allow some thrust line adjustment, although I find that to not be necessary.

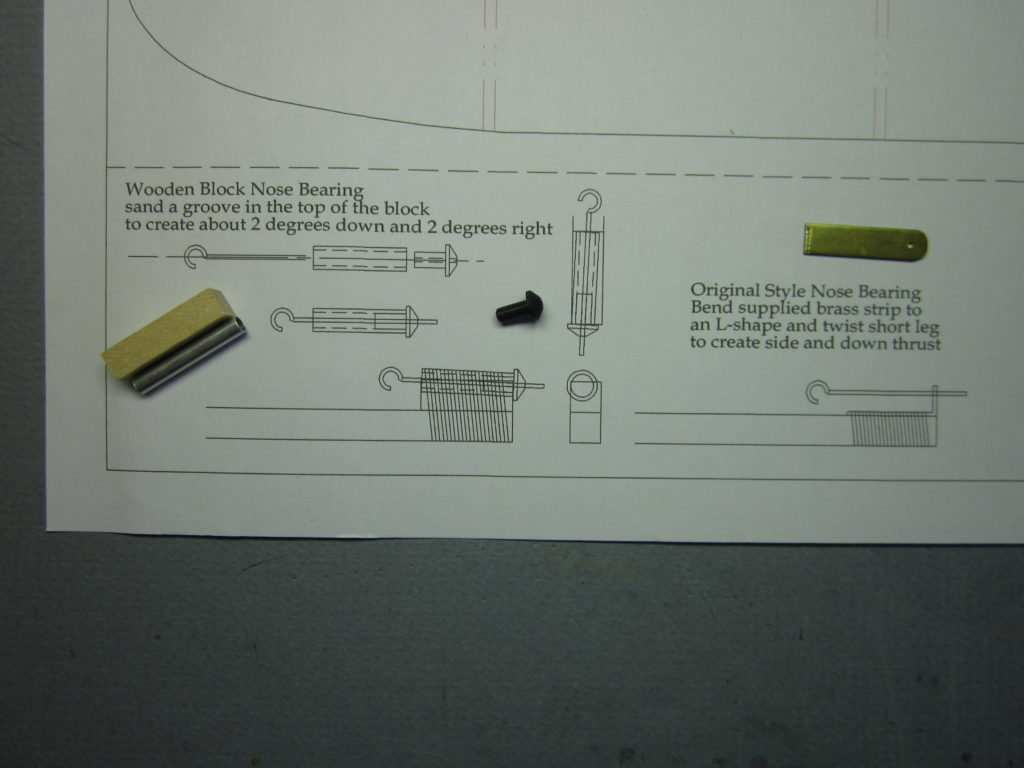

Prop shaft bearing from the volare kit

George Bredehoft supplies parts for two different prop shaft bearings in his Volare kits. One is a 1/4″ wide strip of sheet brass with a hole drilled in one end. The other is a block of balsa, some 1/8″ aluminum tube and a Peck bearing that fits into the tube. I have seen this done with a Peck bearing at both ends of the tube. The Peck bearing could be used alone.

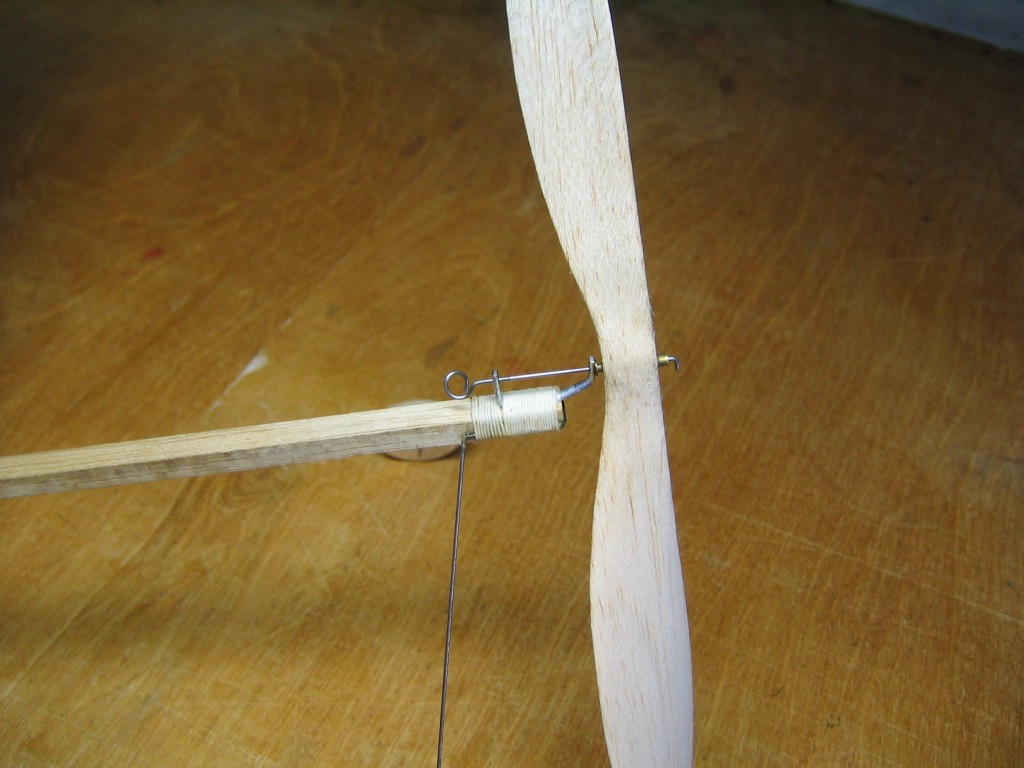

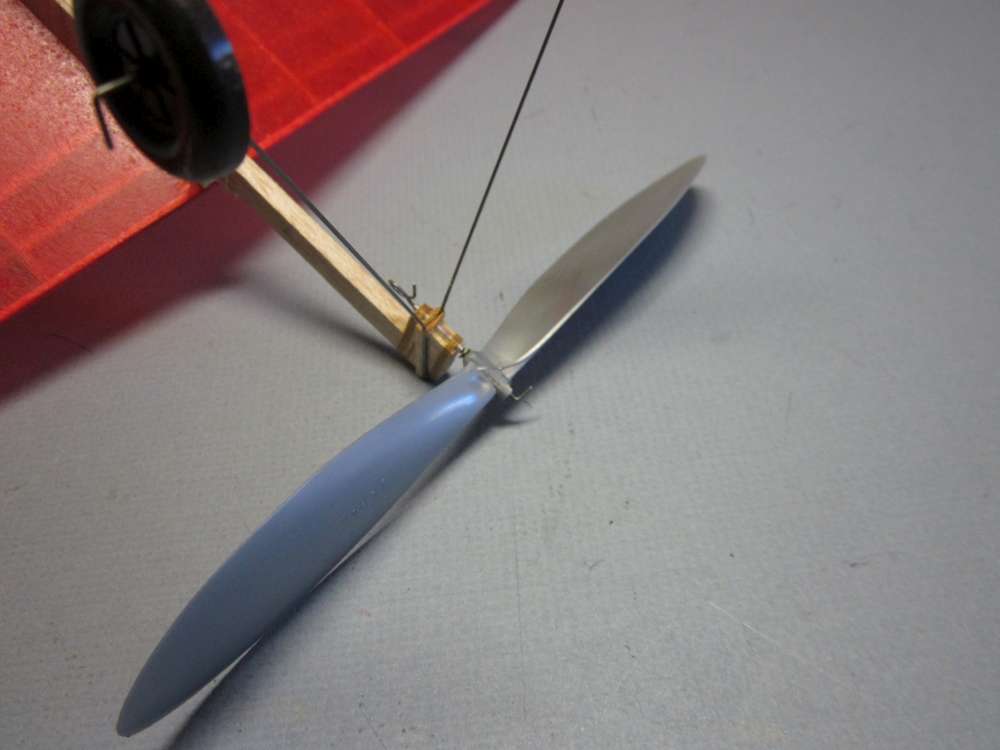

Block and tube bearing

Another option would be a block of balsa and a short piece of 1/16″ brass or aluminum tube. This shows that kind of bearing on a Sky Bunny. The balsa block and tube allow you to set side thrust and down thrust any way you like them. I like to keep things simple.