An Internet discussion of the Blue Ridge Special expressed regret that this model is currently unavailable from the manufacturer. (As of April 2015, the kit is available again at Blue Ridge Models.) Bill Kuhl built one from plans. You can see his discussion and video HERE. Bill has also built rubber powered planes from foam. I decided to combine those ideas, building a copycat from foam.

It was a one day build. Actually, two evenings. One to make the patterns and cut out parts, the second to glue everything together and take it flying.

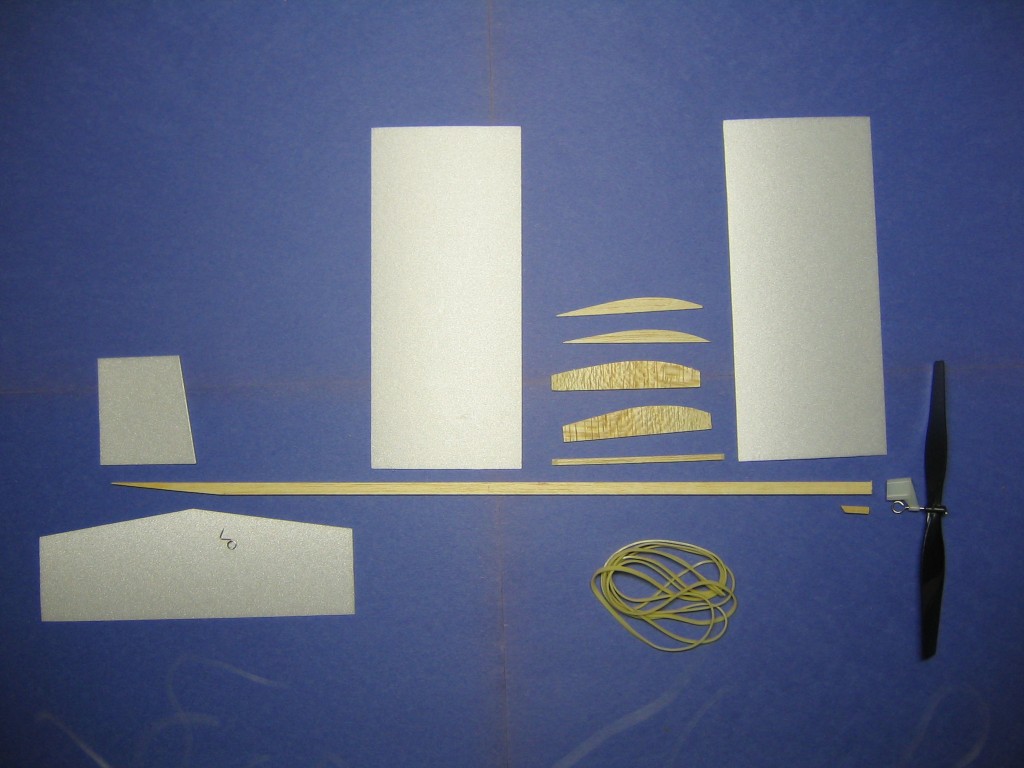

Using 1 mm white foam to make a Blue Ridge Special copycat, here are the parts for the Snowy Mountain Special, or as we say in California, Sierra Nevada Special. Not shown: two dental bands and an O-ring. Dimensions per Jim Moseley, who had a plan.

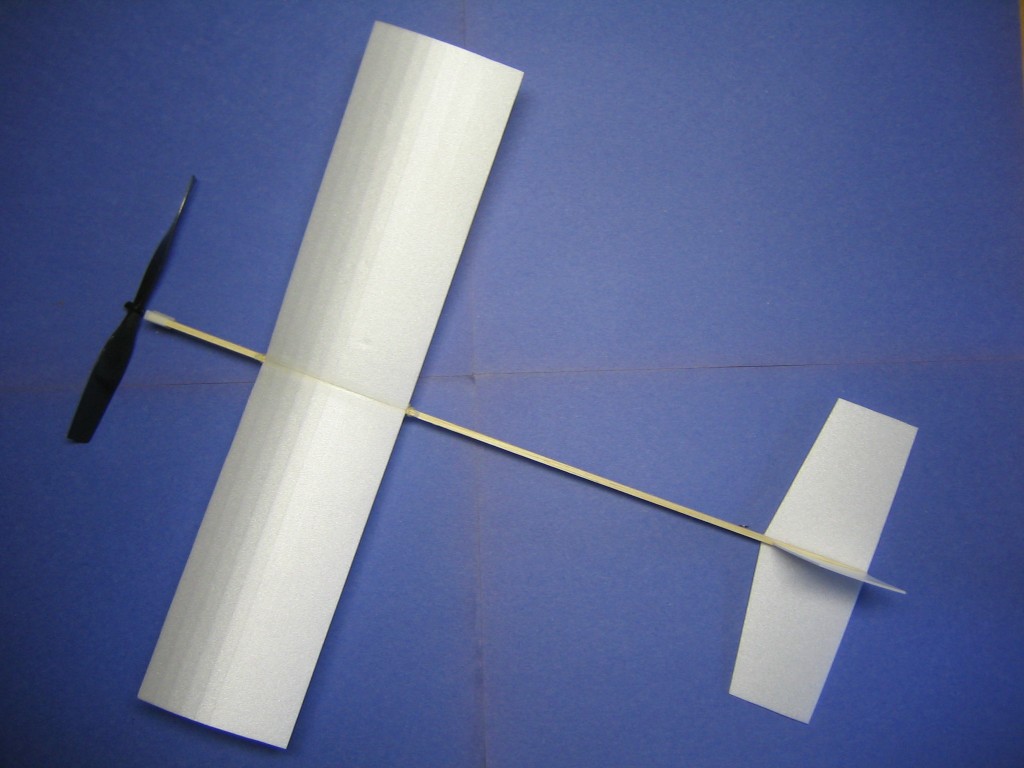

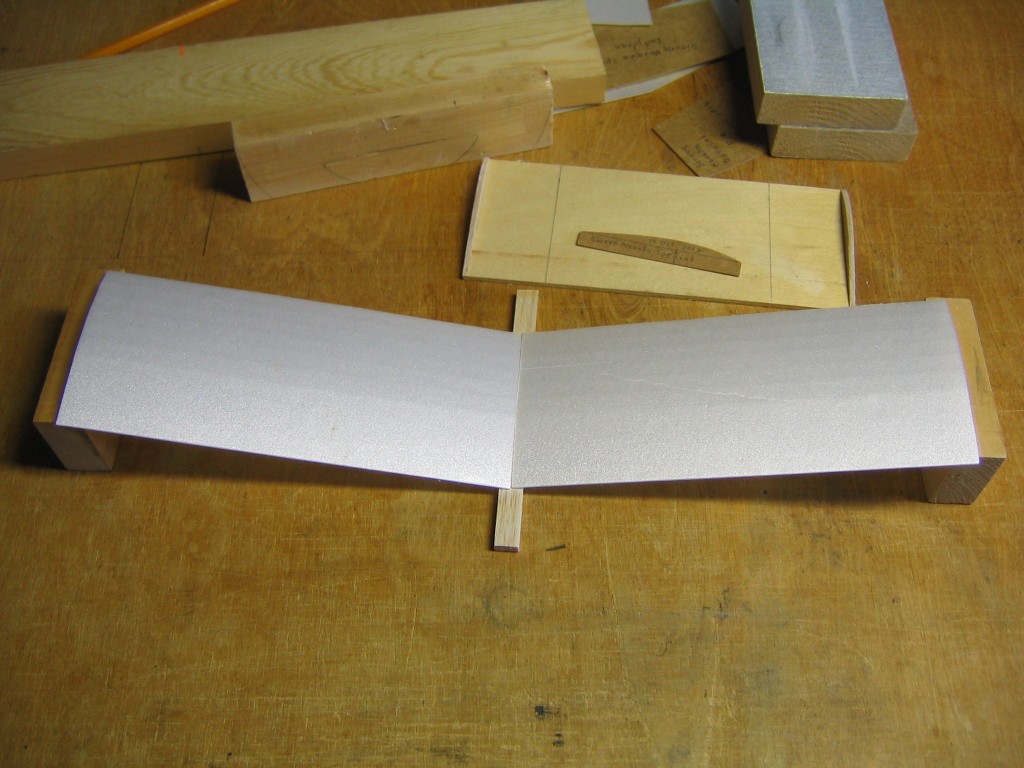

Using 1 mm white foam to make a Blue Ridge Special copycat, here are the parts for the Snowy Mountain Special, or as we say in California, Sierra Nevada Special. Not shown: two dental bands and an O-ring. Dimensions per Jim Moseley, who had a plan. The finished plane. Built very much like the foam Squirrels, except with 1 1/4″ dihedral under each wing tip. Weighs 9.8 grams. Motor is a 25″ loop of 3/32″, braided, comes down to 22 1/2″. Weighs 2.5 grams. Fin camber and incidence for right turn. Without the motor, balanced at top of camber, it makes a nice slow, stable glide. I put the motor on and slid the wing to balance at the high point of camber, 40%.

The finished plane. Built very much like the foam Squirrels, except with 1 1/4″ dihedral under each wing tip. Weighs 9.8 grams. Motor is a 25″ loop of 3/32″, braided, comes down to 22 1/2″. Weighs 2.5 grams. Fin camber and incidence for right turn. Without the motor, balanced at top of camber, it makes a nice slow, stable glide. I put the motor on and slid the wing to balance at the high point of camber, 40%. I went over to the park in the evening for trim test flights. 2,400 turns. Flew quite well, nice and steady, turning right, well balanced, but a lot of vibration. First flight went up maybe 20 feet and drifted diagonally across the field, making many circles, going out through the trees and landing in the street. About 240 turns remaining. No time, but my impression was well over a minute. I judged it to be banking too steeply to the right. I found the prop shaft had right thrust, so I bent the prop hanger to straight ahead. Next windup for video, it circled right more tightly, didn’t climb as much, spent most of the time about waist high, video timed at 56.47 seconds. Found the prop shaft was back at right thrust. Must have bent it back during windup. Too much wind drift for more ambitious flights. I needed to balance the prop anyway.

I went over to the park in the evening for trim test flights. 2,400 turns. Flew quite well, nice and steady, turning right, well balanced, but a lot of vibration. First flight went up maybe 20 feet and drifted diagonally across the field, making many circles, going out through the trees and landing in the street. About 240 turns remaining. No time, but my impression was well over a minute. I judged it to be banking too steeply to the right. I found the prop shaft had right thrust, so I bent the prop hanger to straight ahead. Next windup for video, it circled right more tightly, didn’t climb as much, spent most of the time about waist high, video timed at 56.47 seconds. Found the prop shaft was back at right thrust. Must have bent it back during windup. Too much wind drift for more ambitious flights. I needed to balance the prop anyway.

I wonder what it will do when I crank it up. It will need still air and a big field.

For those who would like to build one, here are some details. This is not a full tutorial. The necessary skills are taught in the linked tutorials.

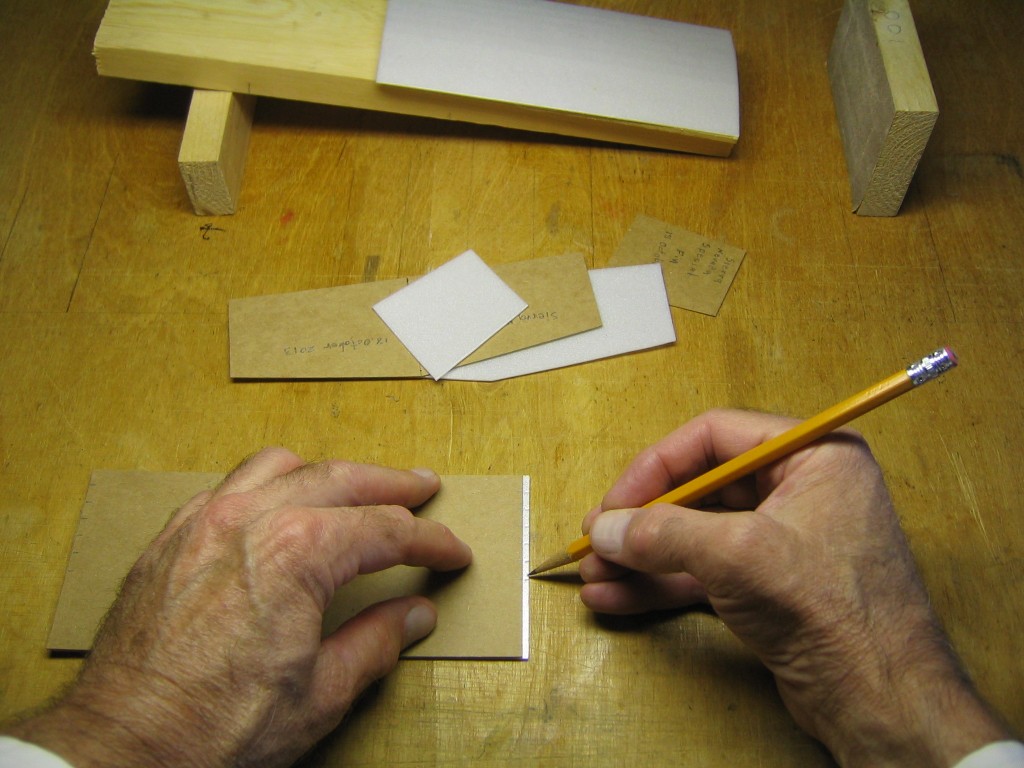

Surfaces are 1 mm foam from RCFoam. Heavy card from a cereal box was used to make patterns. The patterns take a while to make, but cutting around them to make parts goes quickly. If your foam came off a roll and has some curve to it, align the patterns along the straight direction. Orient the curve to match the airfoil on the wings.

Wing panels are 3 1/16″ x 7″. The extra 1/16″ is for camber. The panel must fit the curved airfoil, not just go straight across. Final chord will be 3″. The camber not only makes a more effective airfoil, it provides much improved strength.

Forming the camber starts with marking the ends of the wings at 10, 20, 30, 40, 50 and 60% from the leading edge on the bottom surface. The foam does not take pencil marks well, but the pencil will leave a small crease. Make similar corresponding marks on the opposite end of the wing.

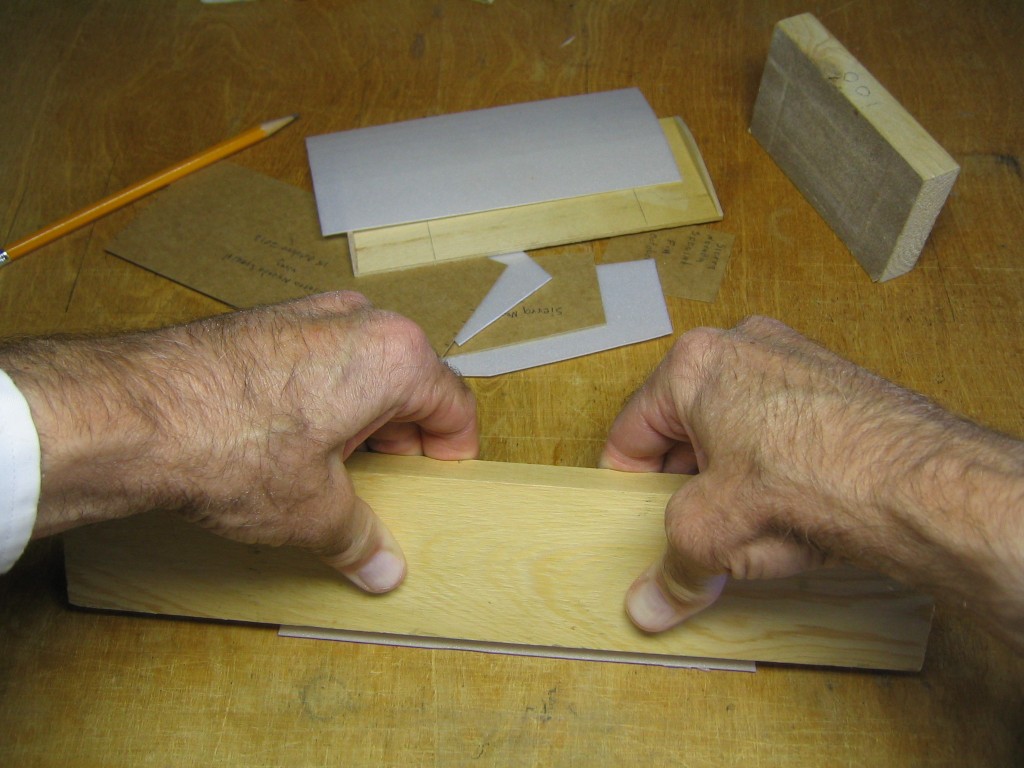

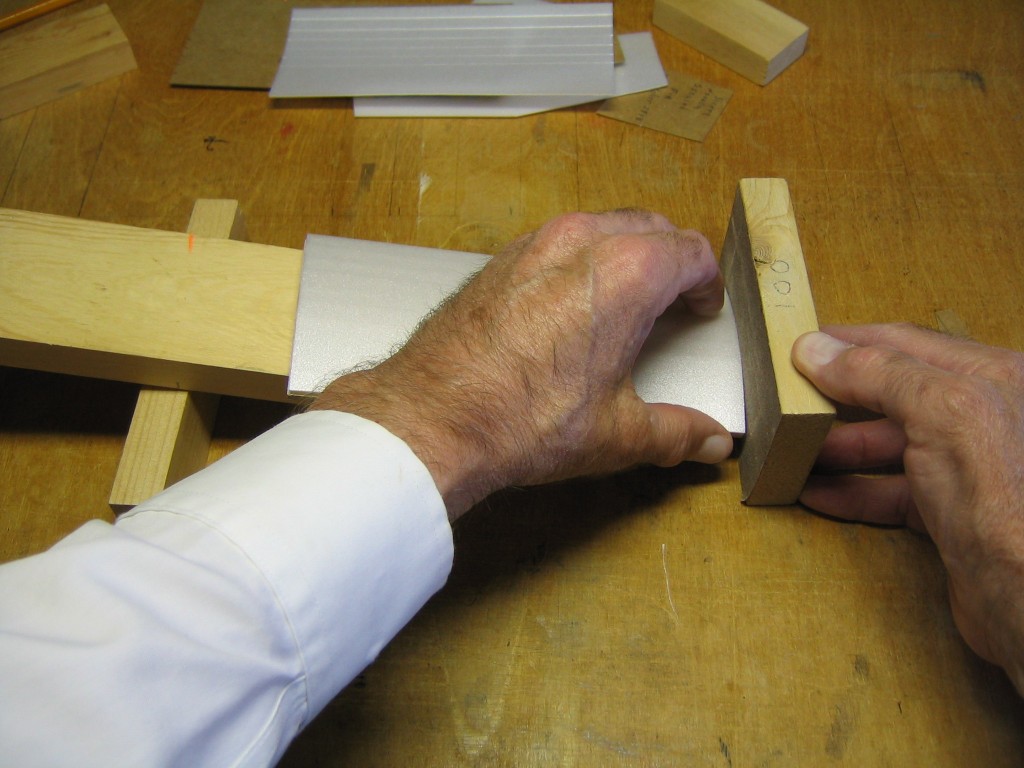

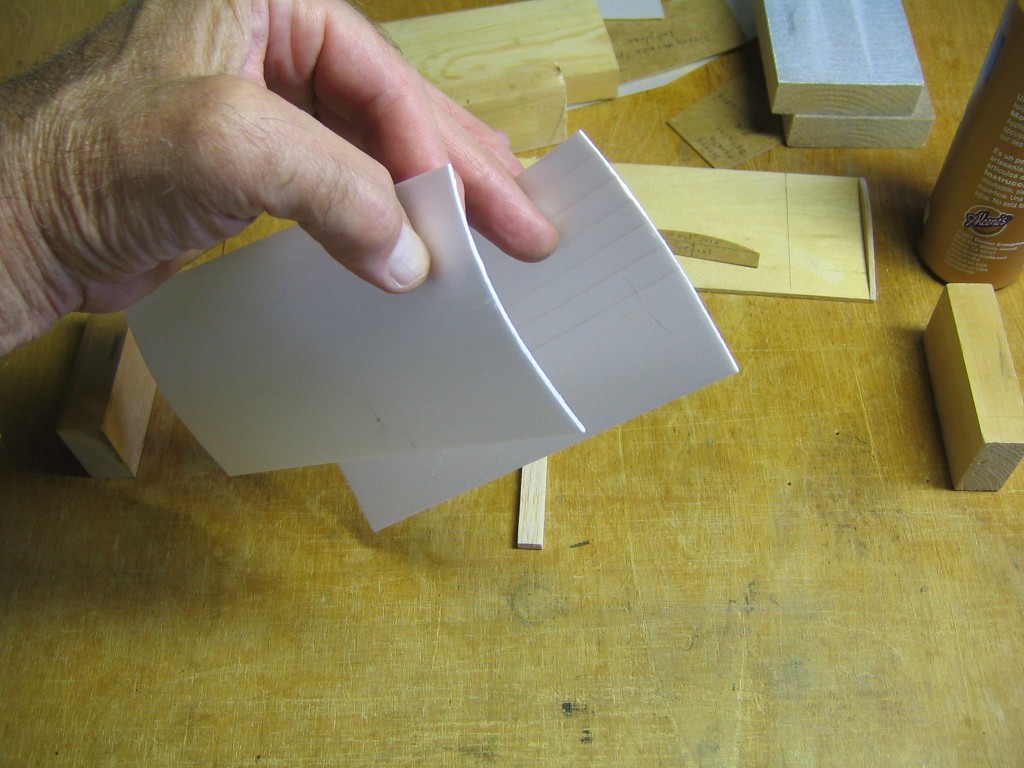

Place a block of wood with one edge aligned between the corresponding marks. Here I am showing the second fold for clarity.

Hold the back of the wing against the block to fold the crease.

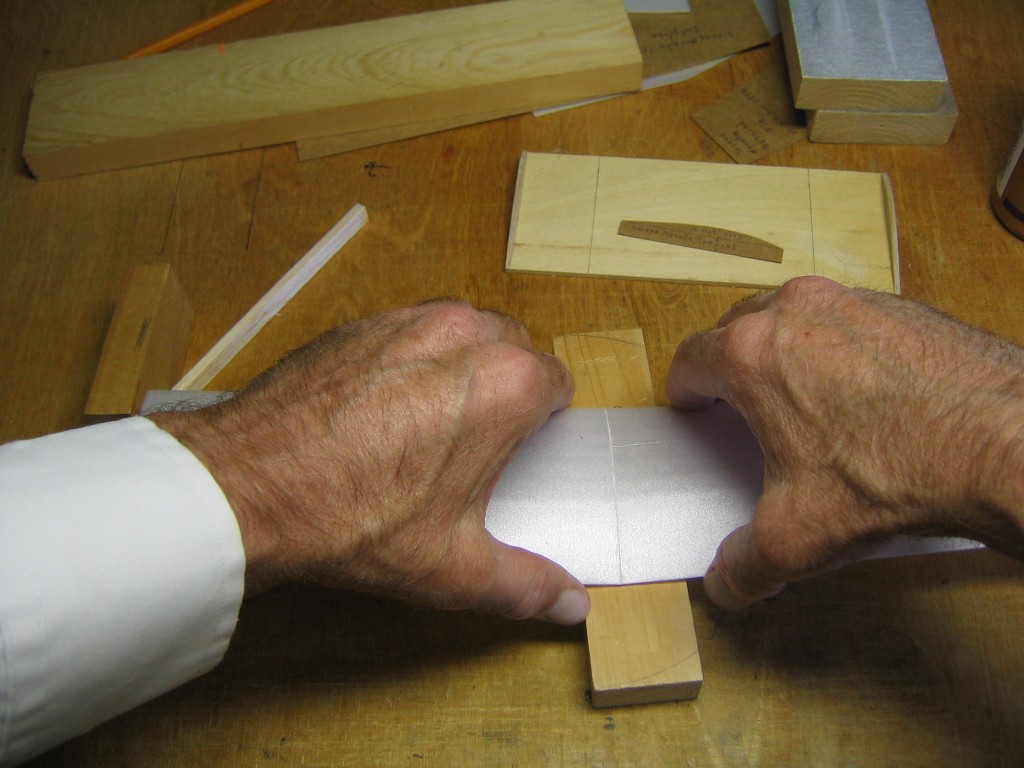

Press the wing against the back of the forming block with another block to make a sharp crease.

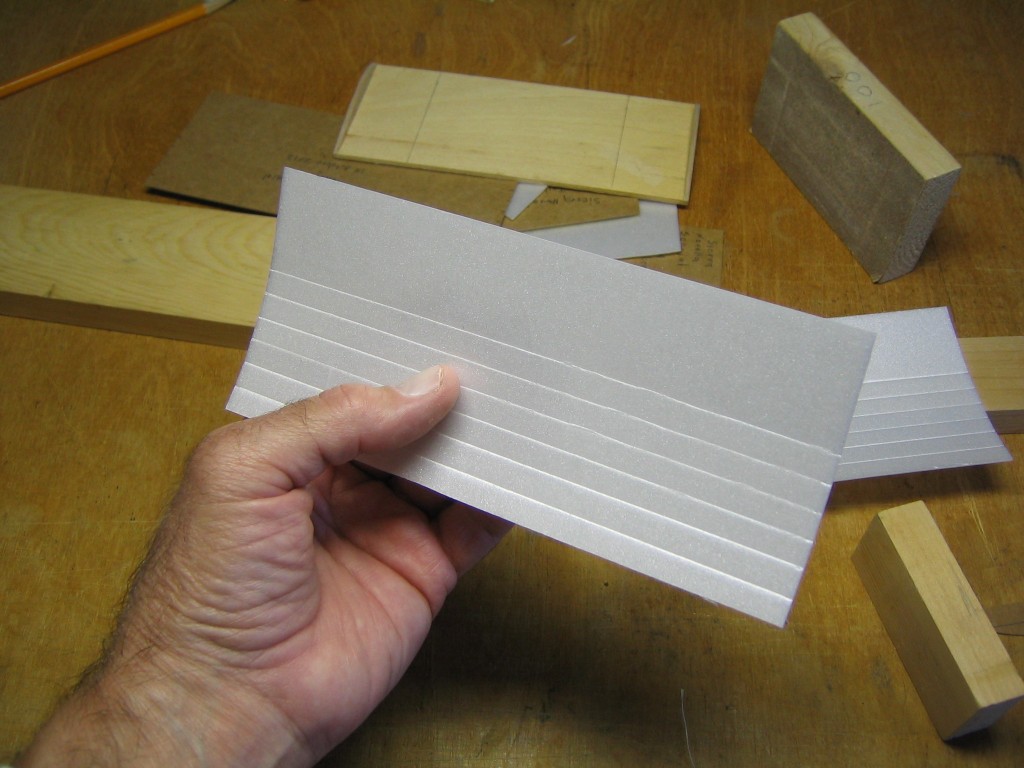

When you get done, there will be six creases forming a gradual curve in the wing.

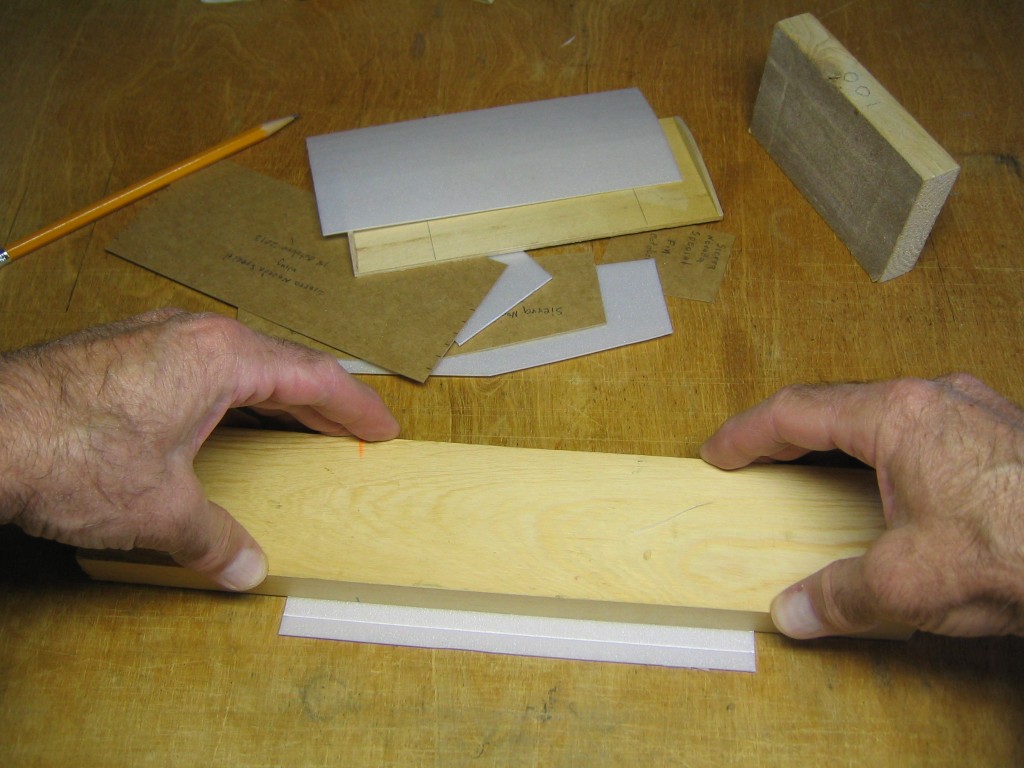

Press the leading edge against the table top and use your fingers to adjust the bends until the curve matches the airfoil. The crease formed wing has a curved airfoil shape that is higher in the middle than on the ends.

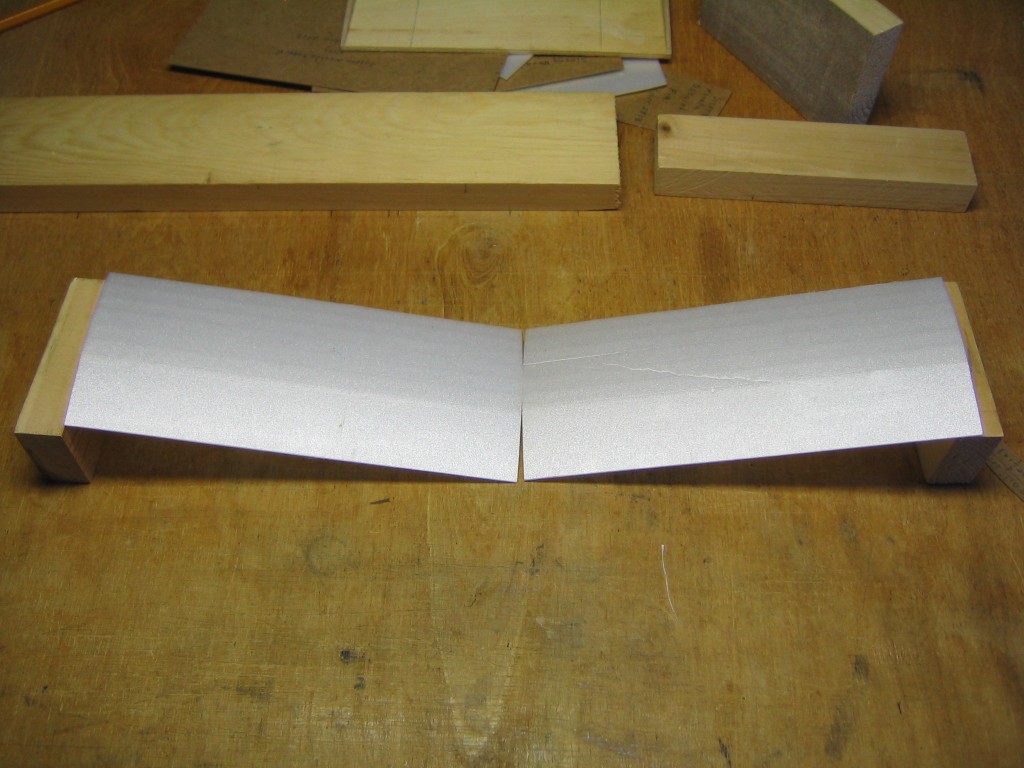

If we put the wings end to end and raise the tips to form the dihedral angle, the high points touch, but there is a gap at the leading and trailing edges. This will make a very poor glue joint. It is necessary to remove a thin gore of material from the inside ends of each wing.

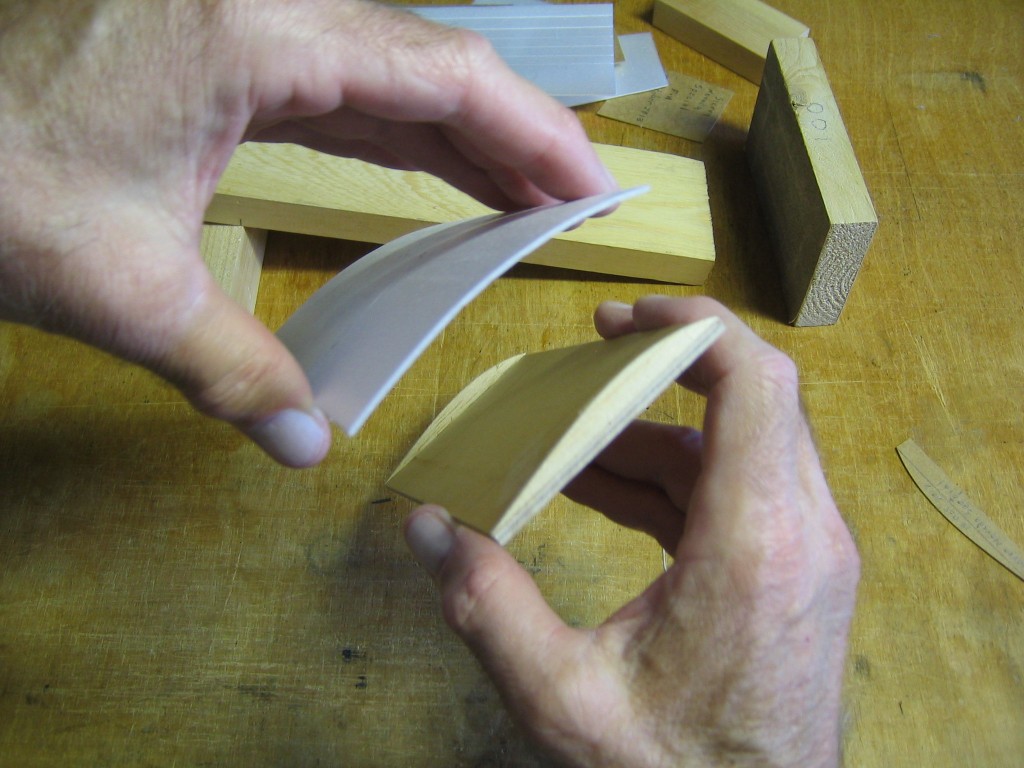

A way to do this is to place the wing on a form board like this. This one was made for 1/16″ sheet balsa wings, using a couple 1/8″ wide ribs glued to each end of a piece of plywood. For this soft foam, there should be more ribs in between the ends to give better support to the soft foam, or a form should be carved from a solid block.

The form is placed on a board that is blocked up to the proper dihedral angle and the end of the wing is sanded down to form a bevel. Press the wing gently to the form at the leading and trailing edges and at the high point. Sand away only the upper curve, do not sand any of the leading or trailing edge away.

Now when the wings are placed together, there is no gap.

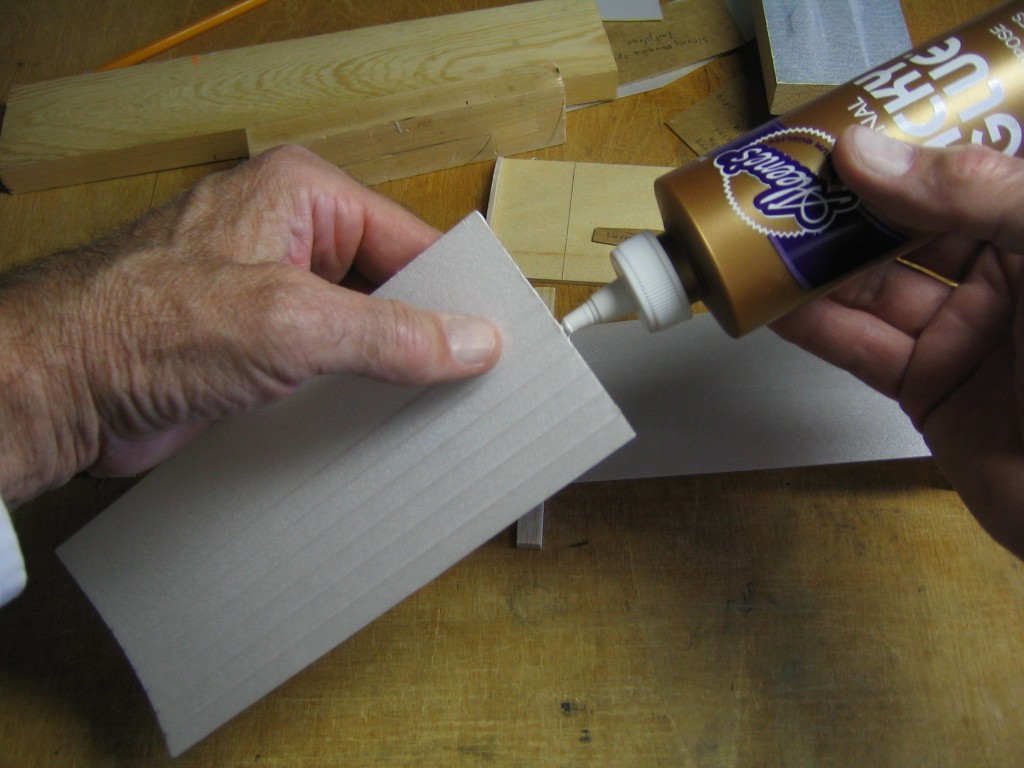

Run a thin bead of glue along each mating edge.

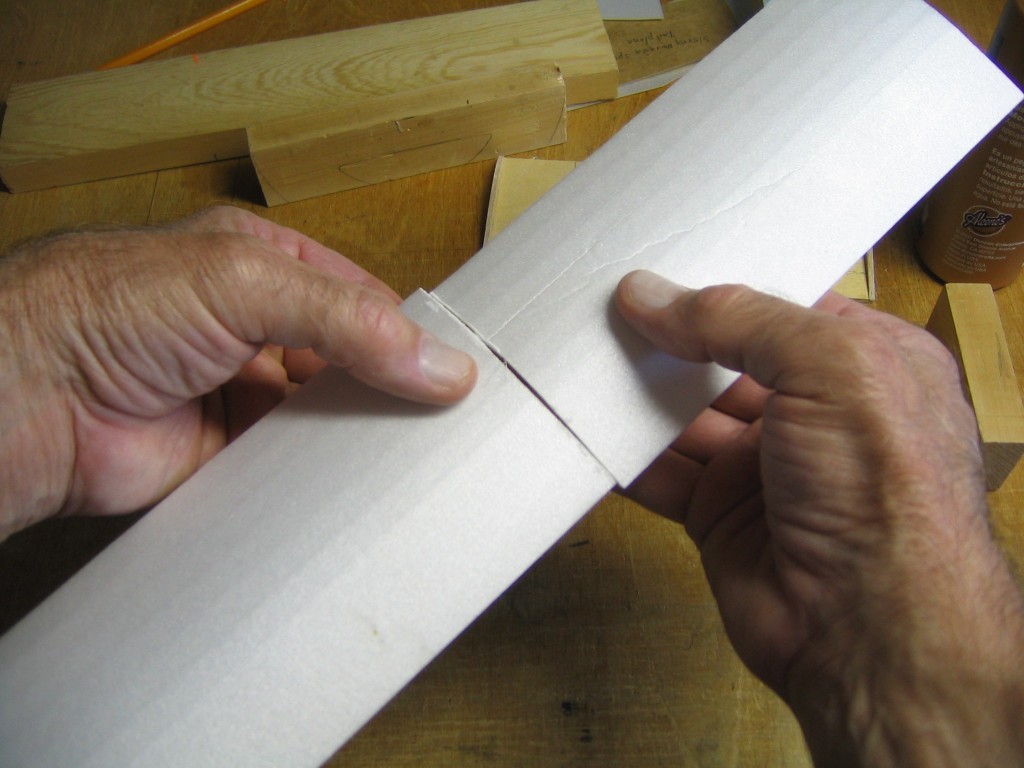

Rub the ends together to spread the glue uniformly in the joint area.

Let the glue get tacky.

Put the wings down on a block with the leading and trailing edges aligned, then raise the tips until the high points come together. Adjust as necessary to get a clean joint. Hold them until the glue takes hold.

Once the glue takes hold, you can set the wing down to dry. Later you can run a bead of glue into the join on top of the wing and fair it in with a wet fingertip. There is no need to add glue underneath, since this will be glued to the wing saddle later.

Tailplane is 6 1/2″ span, 2 1/4″ root chord, 1 3/4″ tip chord.

Fin is 2 3/16″ span, 2″ root, 1 11/16″ tip. Fin is deflected about 1/32″ to give right turn. Start with just a couple dabs of glue in case you decide to change it.

(The kit plan that I now have shows the fin to be 2 1/8″ span, 2 1/8″ root chord and 1 3/16″ tip chord.)

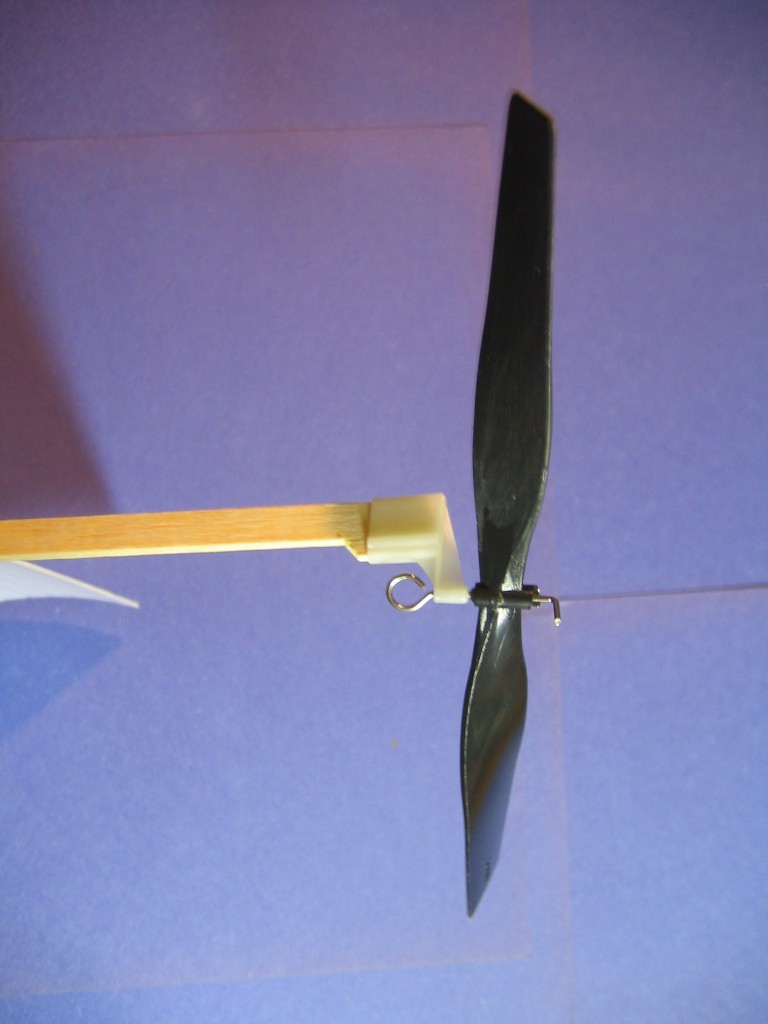

Stick is 1/8″ x 1/4″ x 15 1/2″ of 10# medium hard balsa. (It was supposed to be 15 1/8″) Lighter end is tapered in last 2 3/8″ from full depth to nothing. Be sure the taper is sanded square to the sides. See the Foam Squirrels tutorial on how to do this HERE. Prop bearing shim is 1/2″ of 1/8″ square, back end cut at 45 degrees, glued to the under side of the stick at the front end, same side as the tailplane taper and motor hook.

Prop bearing shim is 1/2″ of 1/8″ square, back end cut at 45 degrees, glued to the under side of the stick at the front end, same side as the tailplane taper and motor hook.

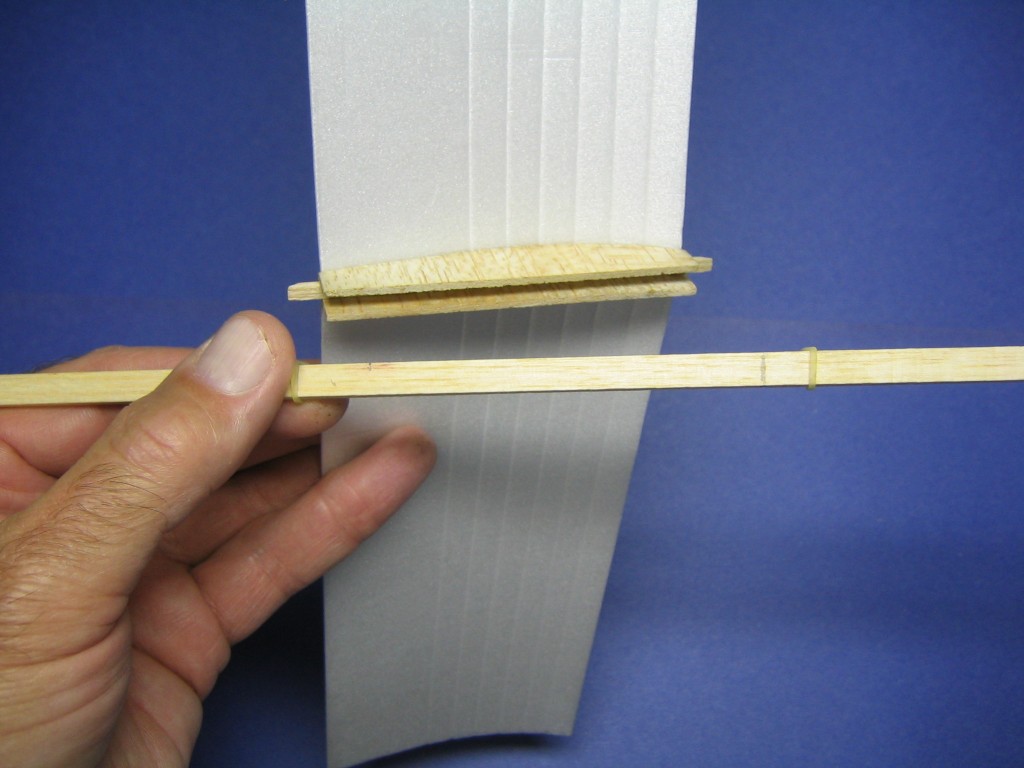

Wing hold down stick is 1/16″ x 1/8″ x 3 1/2″ hard balsa. Held down with two stout 3/16″ dental elastics.

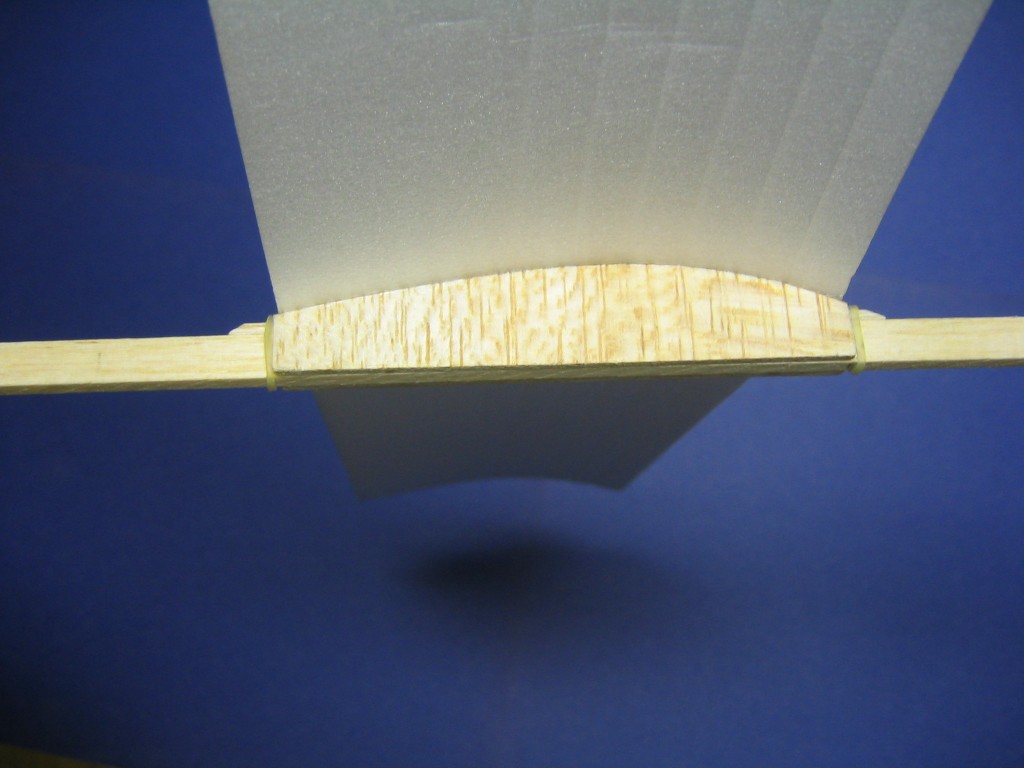

Two wing mount side plates are cut from 1/16″ x 7/16″ x 3″ of medium hard balsa with grain running across short side. The upper 1/4″ of this is cut to airfoil shape, 1/4″ maximum camber at 40% = 1.2″. Zero incidence; zero lift line incidence and prop downthrust angle combined are sufficient to produce plenty of lift, about 8 degrees. These are cut around a stiff cardboard template.

Two wing mount fillers are 1/16″ x 1/4″ x 3″ medium soft balsa, grain lengthwise, cut to match the airfoil shape using the top of the same template. The fillers are glued to the side plates with the 1/4″ and 1/16″ sticks spacing them up from the bottoms of the side plates. Be careful to make a right and a left, they are not the same! These are placed on a board, side plate down, and the board tilted up to the dihedral angle under each wing. A vertical sanding block is used to sand the taper across the tops, being careful to not sand away too much. The two halves are carefully aligned, bottom edges on the tabletop, 1/8″ wide stick between them, sides vertical between pressing blocks, and glued together. Then the hold down stick is added to complete the wing saddle. This shows how the motor stick fits into the slot in the wing saddle.

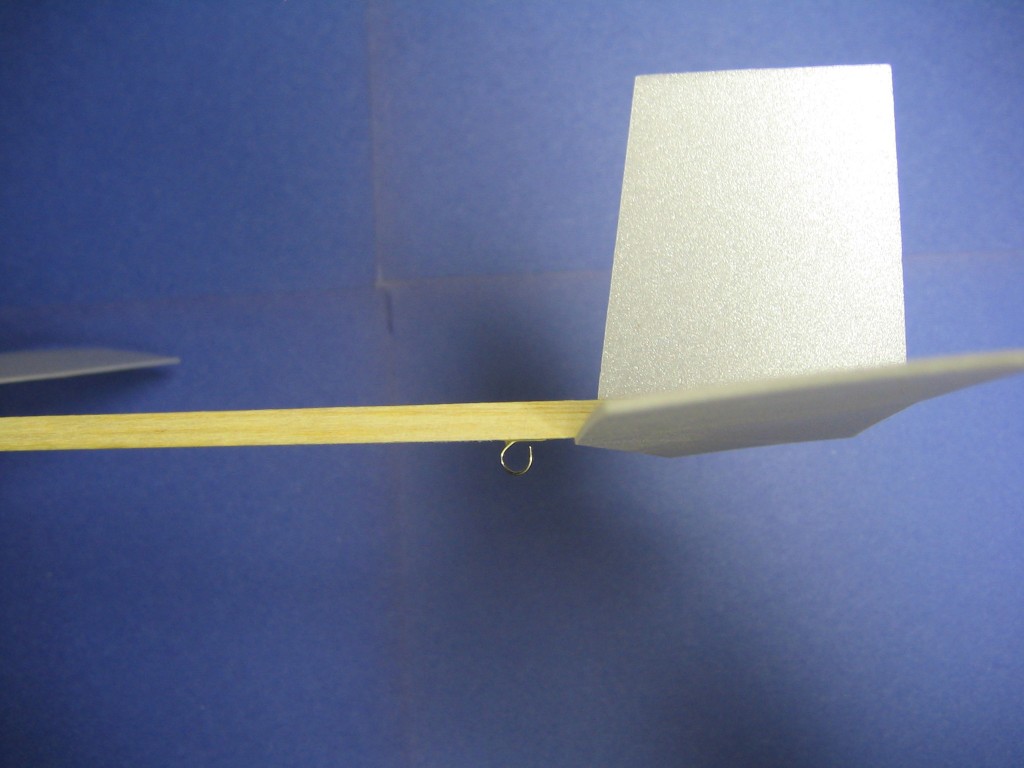

This shows how the motor stick fits into the slot in the wing saddle. This shows how the wing saddle is held to the motor stick by two dental elastics. When you get the wing where you want it, mark the location in pencil on the stick.

This shows how the wing saddle is held to the motor stick by two dental elastics. When you get the wing where you want it, mark the location in pencil on the stick. Motor hook is my AMA Cub standard loop made from a pin. See the AMA Cub Master Class HERE on EndlessLift for directions (about 2/3 down the page). The loop holds the back end of the motor up off the stick. Glue it securely, then glue it again. You can wrap and glue thread around the part that lies along the stick for added security, if you like.

Motor hook is my AMA Cub standard loop made from a pin. See the AMA Cub Master Class HERE on EndlessLift for directions (about 2/3 down the page). The loop holds the back end of the motor up off the stick. Glue it securely, then glue it again. You can wrap and glue thread around the part that lies along the stick for added security, if you like.

Prop is Midwest MPC 6″ black prop assembly, same as comes in the Dandiflyer and other kits. The blade opposite the MPC label was heavy. I took 0.5 gram off to balance it. Shave the back of the heavy prop blade with a kitchen pairing knife to get it to balance. Otherwise the plane will vibrate. Put a bit of fine machine oil on the prop shaft.

Test motor was 25″ loop of 3/32″, braided, could be adjusted later based on flight tests. On two check flights made yesterday I did not gather the necessary data to size the motor.

Plane with motor on was balanced at the 40% crease and flew fine. With shaved prop, it now weighs 9.3 grams without the motor.

This was a great instruction. I made one and it has a great flight, thanks.

Had a ball building and flying this model. Many years have passed since I last built a rubber powered airplane but the exhilaration of a successful flight remains. Thank you for providing such a detailed build log.

Hola, donde puedo conseguir el plano? Gracias

Hi, where can I get the plan? thanks

There is no plan for the Sierra Nevada Special. It is simple enough to not need a plan. Most of the parts are simple rectangles or trapezoids and the dimensions are given in the text. You lay out the patterns on card to make the templates for cutting out the foam. The wing saddle template must be drawn using a drafting curve. The dimensions are given in the text and the pictures make it clear. The side plates must extend below the base of the airfoil to fit on either side of the stick. They must also be long enough to include the thickness of the hold down stick. The center ribs are glued to each side plate which are then sanded to make the proper dihedral angle before the two are glued together. See the tutorials for the foam Squirrels and the Poly Wog for more construction details. The same methods will work here with minor adaptation. The Poly Wog shows the use of Sig formed airfoil sheet to form the dihedral during sanding.

Wow! I love this!

Now this is something that would make a beautiful kit!